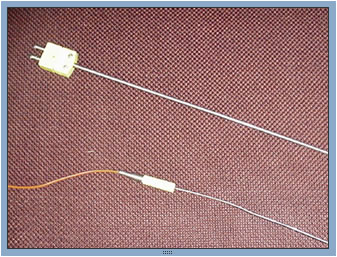

Temperature sensing in a microwave system is not much different than in conventional oven or furnace. The most common form of temperature measurement in a microwave chamber is a thermocouple or RTD probe. These probes come in many lengths and diameters. They are also available in grounded and ungrounded configurations. Ungrounded probes work well to eliminate any system noise on their signal lines, but are slightly slower in response time.

These measurements probes work well when inserted through a compression fitting

that is mounted on the microwave chamber wall. A compression fitting

seals around the shaft of the probe causing a tight microwave seal. Although

thermocouples are available in bare wire configurations, they are not

user friendly in the microwave chamber due to their inability to seal

to the chamber walls or surfaces. Probes that are fed through a door

or hole in the microwave chamber without proper compression seal act

as a coaxial cable path for the microwave energy to escape.

These measurements probes work well when inserted through a compression fitting

that is mounted on the microwave chamber wall. A compression fitting

seals around the shaft of the probe causing a tight microwave seal. Although

thermocouples are available in bare wire configurations, they are not

user friendly in the microwave chamber due to their inability to seal

to the chamber walls or surfaces. Probes that are fed through a door

or hole in the microwave chamber without proper compression seal act

as a coaxial cable path for the microwave energy to escape.

Another common form of temperature measurement used primarily in non-contact

measurement and High Temperature applications is the Pyrometer. The pyrometer

is a non contact measurement device that looks through a carefully designed

penetration in the microwave chamber to focus on a material that is being processed.

(heated, dryed, cured, etc) Pyrometers use optical sensing and require access

to a visible line of sight to the material being processed.

For further information on sensing temperature in a microwave application contact

our engineering staff or click on one of the following links to be forwarded

to a temperature sensing manufacturer.

MICROWAVE MATERIALS TECHNOLOGIES, INC. TENNESSEE

Website Design by T2 Design.