About Microwaves

The list of advantages for using microwave energy is expanding daily. Materials that are poor thermal conductors are difficult materials to heat rapidly and in a uniform manner using convection or thermal conduction. Microwave energy can penetrate materials of this nature to provide rapid volumetric heating.

Electromagnetic Energy known more by consumers as microwave energy has many advantages over conventional heating techniques. The most widely recognized advantage is rapid heating used heavily in the preparation and reheating of food products. Other less published benefits include uniform (volumetric) heating, ultra-high temperature heating, non-contact heating, uniform drying, drying and often partial drying of wet extrusions, rapid dehydration of tissue, chemical vapor deposition, accelerating chemical reactions, curing of thick laminates, rapid curing of foam insulations, drying lumber, pasteurizing food, sterilizing food, , etc, etc. The list of advantages for using electromagnetic energy is expanding daily.

Electromagnetic Energy known more by consumers as microwave energy has many advantages over conventional heating techniques. The most widely recognized advantage is rapid heating used heavily in the preparation and reheating of food products. Other less published benefits include uniform (volumetric) heating, ultra-high temperature heating, non-contact heating, uniform drying, drying and often partial drying of wet extrusions, rapid dehydration of tissue, chemical vapor deposition, accelerating chemical reactions, curing of thick laminates, rapid curing of foam insulations, drying lumber, pasteurizing food, sterilizing food, , etc, etc. The list of advantages for using electromagnetic energy is expanding daily.

Materials that are poor thermal conductors are difficult materials to heat rapidly and in a uniform manner using convection or thermal conduction. Microwave energy can penetrate materials of this nature to provide rapid volumetric heating.

Let MMT assist you in your material processing needs. With over 30 years of experience, our staff can provide solutions to your difficult heating requirements.

There are a number of materials that heat well in a microwave field such as ceramics, wet extrusions, laminates, alcohols, acids, silicon carbide, insulating foams, oils, carbon, etc. The unique thing about heating materials with a microwave field is that each material couples (absorbs energy) differently. Many different materials have similar abilities to absorb microwave energy.

The most important thing to understand when considering using microwave energy is how the energy heats the material. A microwave is an electromagnetic sign wave at some frequency. For most residential and some commercial applications, that frequency is 2450 Mhz. This means that the wave form changes polarity (positive to negative and back) 2 billion 450 millions times per second. In the case of polar solutions like water, the molecules try to align themselves with respect to the microwave field.

Because the field is changing back and forth so many times per second the molecules create friction. This friction is dissipated in the form of heat. In materials that are not polar, microwave energy heats materials by the way of the electrons resistance to flow through the material. If the materials are very conductive such as copper or aluminum, then electrons will flow with very little resistance (Heating) conducting electrical energy.

The “Heatability” or the ability of microwave energy to heat a specific material comes from the electrons’ inability to flow freely. The molecular friction caused by voids in the materials conductivity causes heat. The dielectric properties of materials with regard to temperature and frequency are one of the main tools used to determine the ability of a specific material to heat. This is why it is so important to fully understand the material to be heated. MMT, Inc. uses two dielectric analyzer’s systems to evaluate customer materials.

There are a number of materials that heat well in a microwave field such as food, lumber, human tissue, ceramics, wet extrusions, laminates, alcohols, acids, silicon, insulating foams, oils, carbon, etc.

The unique thing about heating materials with a microwave field is that each material couples (absorbs energy) differently. Many different materials have similar abilities to absorb microwave energy.

Heating materials uniformly is the science centered around how electromagnetic energy is applied. Many elements must be considered when uniform heating is the objective. The ability of the material to absorb is first and for most. The second is the size of the material. The third is the desired temperature or dryness. These conditions are evaluated and fully understood before an engineering design can be applied.

The microwave fields (energy level) are normally the highest at the point where they leave the waveguide transmission path. If a material is positioned directly in front of this opening, the side facing the waveguide would heat faster than the reverse side. This is usually not the desired result. If the material to be heated is 20 ft long, then applying the energy along this length evenly would be very difficult. It is obvious to see that materials come in different sizes and shapes and that to heat, sterilize, dry, cure, sinter, these materials evenly requires a custom design. Contact our staff about your processing needs.

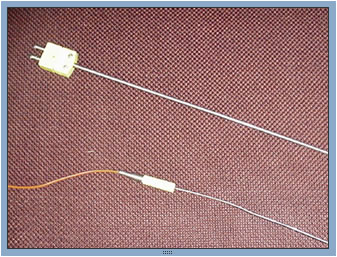

Temperature sensing in a microwave system is not much different than in conventional oven or furnace. The most common form of temperature measurement in a microwave chamber is a thermocouple or RTD probe. These probes come in many lengths and diameters. They are also available in grounded and ungrounded configurations. Ungrounded probes work well to eliminate any system noise on their signal lines, but are slightly slower in response time.

These measurements probes work well when inserted through a compression fitting that is mounted on the microwave chamber wall. A compression fitting seals around the shaft of the probe causing a tight microwave seal. Although thermocouples are available in bare wire configurations, they are not user friendly in the microwave chamber due to their inability to seal to the chamber walls or surfaces. Probes that are fed through a door or hole in the microwave chamber without proper compression seal act as a coaxial cable path for the microwave energy to escape.

These measurements probes work well when inserted through a compression fitting that is mounted on the microwave chamber wall. A compression fitting seals around the shaft of the probe causing a tight microwave seal. Although thermocouples are available in bare wire configurations, they are not user friendly in the microwave chamber due to their inability to seal to the chamber walls or surfaces. Probes that are fed through a door or hole in the microwave chamber without proper compression seal act as a coaxial cable path for the microwave energy to escape.

Another common form of temperature measurement used primarily in non-contact measurement and High Temperature applications is the Pyrometer. The pyrometer is a non contact measurement device that looks through a carefully designed penetration in the microwave chamber to focus on a material that is being processed. (heated, dryed, cured, etc) Pyrometers use optical sensing and require access to a visible line of sight to the material being processed.

For further information on sensing temperature in a microwave application contact our engineering staff or click on one of the following links to be forwarded to a temperature sensing manufacturer.

© COPYRIGHT 2008. ALL RIGHTS RESERVED BY MICROWAVE MATERIALS TECHNOLOGIES, INC. TENNESSEE

Website Design by T2 Design.